About us

History

- 2006 - opening of our new production-plant and warehouse in Erndtebrück

- 2011 - introduction of energy management

- 2012 - opening of our new production-plant in United Kingdom

- 2014 - opening of our new production-plant in Belgium

- 2015 - successful Halal certification for all production sites

- 2016 - opening of our new production-plant in Gemmingen

- 2017 - Expansion EuroMouldings in Nijverdal

- 2019 - Expansion Sanderman Cleaning Group in Hengelo

- 2020 - Foundation: AST Recycling & Rekonditioning GmbH -Start of construction of recycling plant in Hilchenbach

- 2021 - Foundation Cipacks- Creation of our own packaging recovery system

- 2022 - Expansion Joh. Sieben in Heinsberg

Premium Products - Premium Quality

Our products are identified by premium quality. We use a high performance raw material, manu- factured to the highest standard. Our high quality standard is certified by quality management system (ISO 9001:2015). In addition, our containers are tested and approved according to the strict requirements of the ADR (UN-approval). To ensure sustainable products, we have also implemented an Energy Management System (ISO50001) in our manu- facturing process.

Innovative and dynamic

Decades of experience in producing plastic containers and technical knowhow are key-competences of AST. The chemical industry and the food sector appreciate and expect the high level of quality that AST produce. Permanent and continuous invest- ments in our modern plant guarantee state-of-the-art production processes for the manufacture of plastic containers.

Professional and personal service

For AST, Customer Service is key to our success. Listening to our customers and providing them with solutions for their products is the start of a long term relationship. A well placed network of distributors in Europe ensures support for our inter- national business partners. We will find solutions for all of your needs!

Quick, flexible and reliable

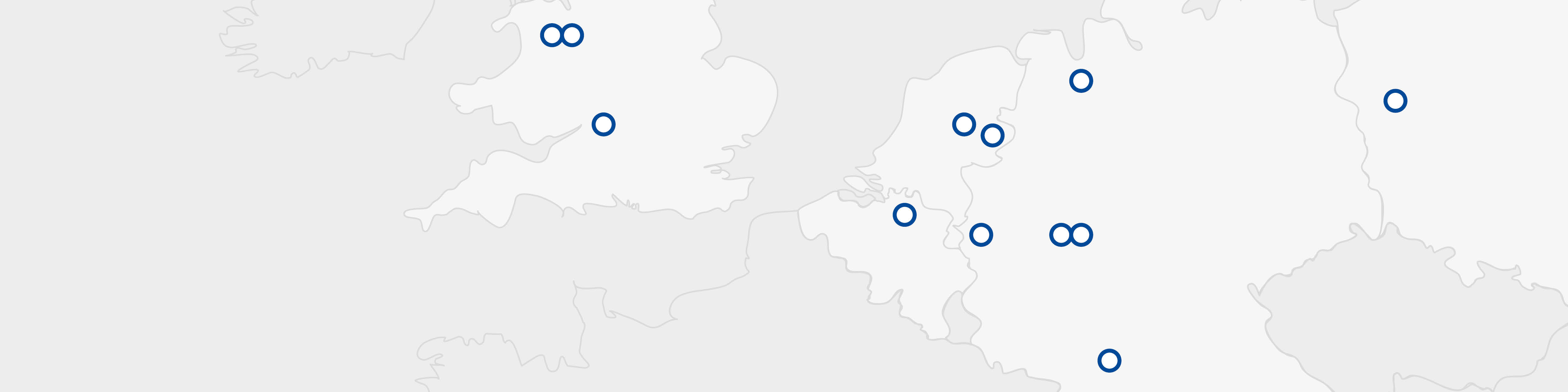

Six production sites: Two in Erndtebrück (Germany), one in Gemmingen (southern Germany), one in Wrexham (UK), one in Hoogstraten (Belgium) and one in Nijverdal (Netherlands) guarantee our short term and flexible ability to supply, due to large storage facilities and the excellent location of our factories. On time deliveries are guaranteed due to well organized production planning, supported by our own fleet of transport.

We close the loop

We focus on a sustainable future and close the loop. With our take-back system CIPACKS (CIrcular PACKaging Solutions), we help you to close the loop together and offer you a complete solution for your company to convert to a circular economy.

We take back used containers and give them a new life.

With our processes, we clean used containers so that they can be reused and return them to the market.

If cleaning is not possible, we recycle them and process them to create a new raw material for our production. With the recycled granulate, we can offer up to 100% recycled products.

www.cipacks.com |